Technical Information

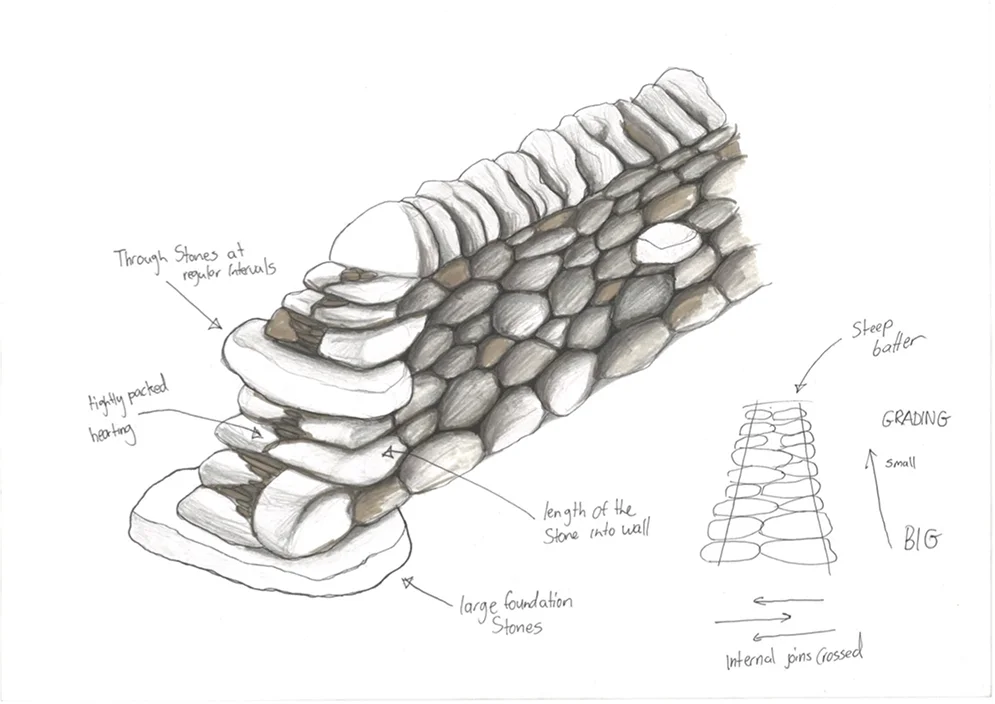

Dry-Stone Walling

Stone and gravity are the only things holding a dry stone wall together. They are in many cases more effective than mortared walls. Drystone walls strengthen overtime as the stones settle and lock into place. They have a built in natural drainage system making them ideal for earth retaining purposes. Drystone walls are less destructive to surrounding plant life than walls built with concrete.

Drystone walls live in harmony with their natural surroundings, making them ideal for gardens and boundary walls. They are often used as a habitat for small animals like lizards and insects.

Cementitious Mortar

Portland cement was designed in the early 19th century and is manufactured using a combination of Calcium Oxide, Pozzolans and gypsum. Cement mortars are the most commonly used mortars in modern masonry practices. With high compressive strength and fast setting times cement mortar has many practical uses however its innate density and hardness can cause problems in some applications.

Due to its lack of "breathability" (moisture travels through capillaries). Issues like Efflorescence (mineral leaching) can occur. This is because the mortar is denser and less porous than the stone itself, causing moisture and minerals to leach through the stone instead of through the mortar.

Image: White residue indicates minerals leaching through the stone (Efflorescence).

Concrete walls restrict moisture travel from one side to the other. This is especially undesirable for dwellings where excess moisture is a major problem for health reasons.

Cement sets primarily by hydration and is prone to shrinking and expanding when in contact with water, this leads to cracks and lets moisture in to the structure. When moisture is trapped within the internal fabric of the wall followed by freezing and thawing cycles the cracks expand and can eventually lead to complete failure of the wall.

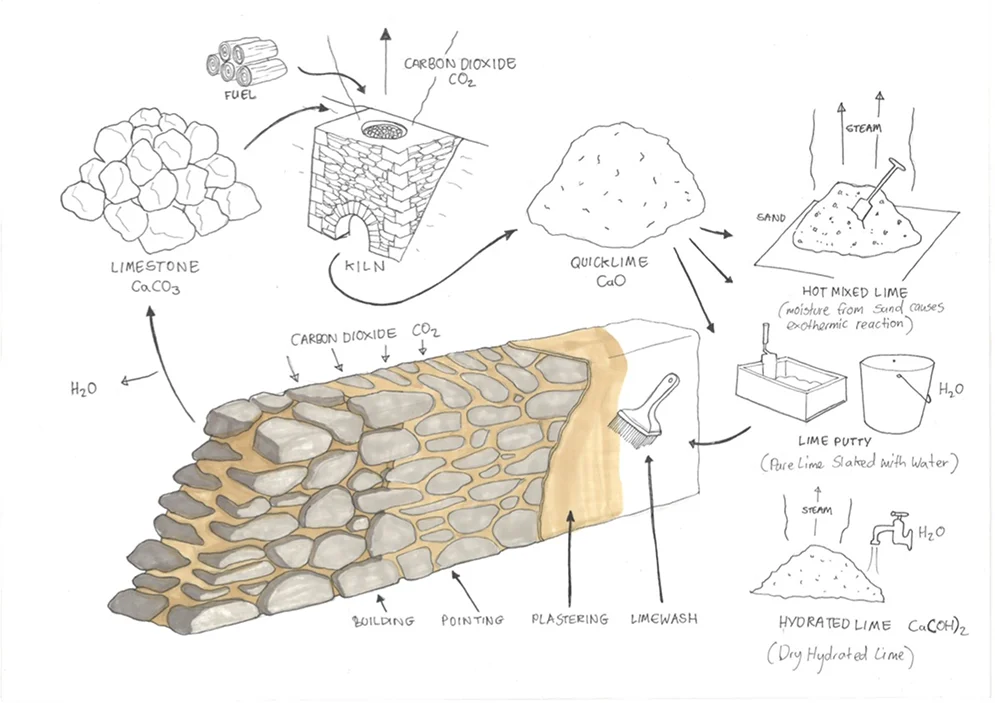

Lime Mortars

Lime Mortar is made first by heating crushed limestone in a kiln to above 900 degrees C, followed by further processing depending on the final product. Pure or near pure Lime Mortars have been used extensively in construction alongside stone through the ages.

Traditionally Lime was used by itself or mixed with other materials such as earth, sand, clay, pozzalans and more to create Lime Mortar. Lime Mortar has many desirable qualities like being self heating and very breathable. Generally speaking, Lime mortar is a sacrificial mortar, and requires appropriate maintenance over time.

Image: The Lime Cycle.

Natural Hydraulic Lime (NHL)

Made from impure, clay-bearing limestone which sets by chemical reaction with water and by carbonation. NHL was popularized during the lime revival in the 1970's once it came to light that the use of cement mortars used to repair historic buildings originally built with Lime Mortar was compromising their integrity. NHL's hydraulic nature means it is great for applications in contact with the sea, canals, rivers etc. Cracking issues may be attributed to the use of NHL mortars if they dry too quickly, they are prone to excessive shrinkage and expansion when used above ground.

Lime Putty

When pure or near pure Calcium Oxide (Quicklime) is "slaked" with the addition of water it created Calcium Hydroxide, when Calcium Hydroxide is exposed to Carbon Dioxide in the air it begins to carbonate, moisture evaporates and the mortar starts to go hard, completing the Lime Cycle. Lime Putty is Calcium Hydroxide that has been submerged in water and usually stored for more than 3 months before being used for masonry building, plastering and lime washing. Lime putty has a dough ike consistency and is used by itself or as a binder.

Hot Mixed Lime Mortar

It is believed that the use of Hot Mixed Mortar was the preferred method used by stonemasons in antiquity. Many historic buildings around the world that are still standing were built with Hot Mixed Lime, usually with the addition of earth and/or sand. The difference between Lime Putty and Hot Mixed Lime is that Hot Mixed Mortar is used directly after the slaking process has taken place. Using the mortar while still hot accelerates water loss, which speeds up the stiffening of the mortar, meaning the stonemason is not restricted by long setting times. Hot mixed Lime mortar has a strong bond and is extremely workable. A good visual representation of these qualities is made when the mortar sticks to the masons' trowel like glue when turned upside down, seemingly defying the laws of gravity.

Image: Hot Mixed Lime Mortar, Illustrating optimal bond and workability.

Further reading and interesting links;